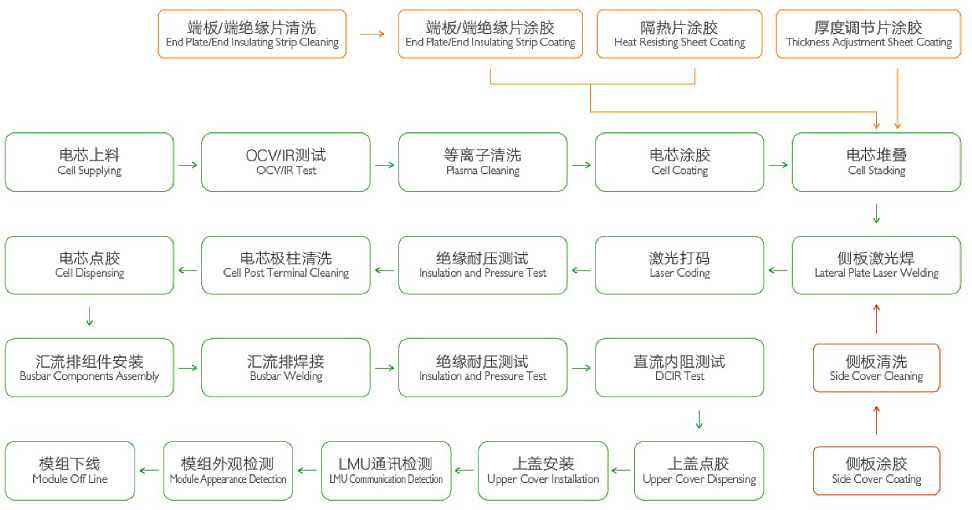

Prismatic battery module automatic assembly production line includes cell feeding, battery disposal detection, cell stacking, side seam welding, Busbar laser welding, module test. It can realize flexibility based on intelligent robot and information based manufacturing.

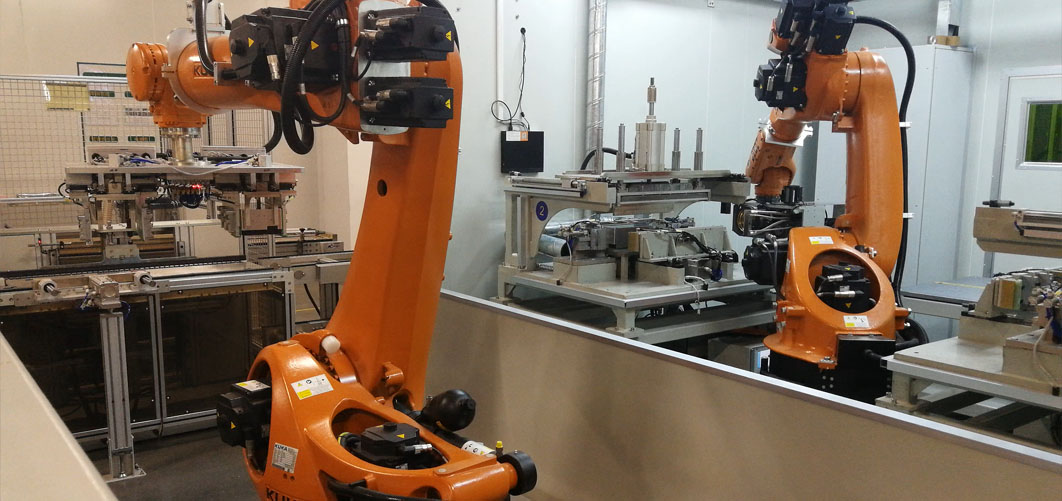

The whole process adopts information acquisition module to do overall monitoring on the whole production line, and uses central control system to do overall control on production process. Production process adopts robot technology instead of manual production. Only few workstations set manual intervention, and it has high degree of automation.

Cell stacking: Robot grabs cells, and puts cells into stacking fixture. Stacking fixture presses stacked cells. After finishing stacking of module, it will generate a barcode. Module barcode will automatically bind cell barcode with information, which will upload to MES system.

Side seam welding: It includes welding room, welding fixture, welding robot, laser device and vibration lens. It adopts high-power imported laser device and vibration lens, which can flexibly define the shape of welding joint and ensure maximum quality of welding joint in mass production. After laser welding, upload module barcode, welding position, laser parameter time, supplier information, batch to MES system for storage and data tracing.

Busbar laser welding:Welding adopts double-station mode, which realizes uninterrupted welding operation and improves the takt time. Robot with vibration lens welds complete busbar to the anode and the cathode of the cell, and uploads the data to MES system. It monitors welding actual power, actual welding speed, actual defocusing amount, gas protection flow, etc. in real time and save these locally. The equipment automatically generates and save these information and upload them to MES system.