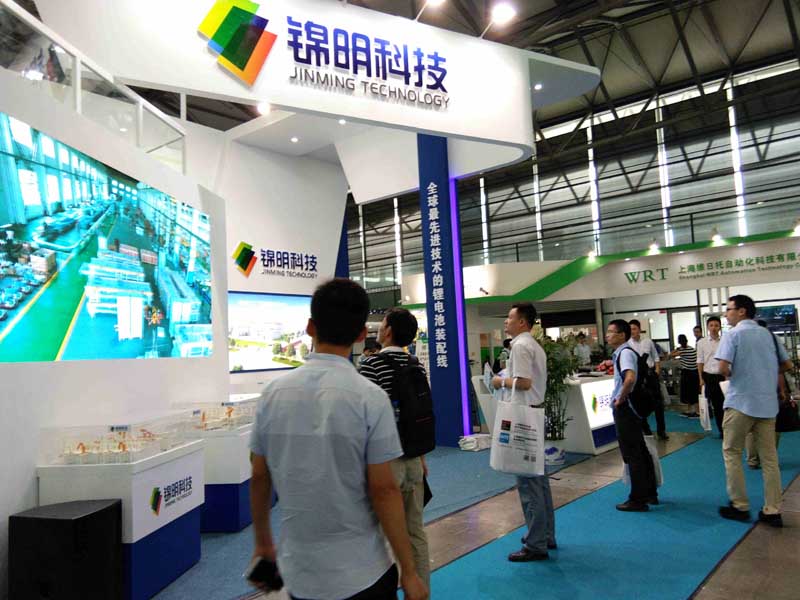

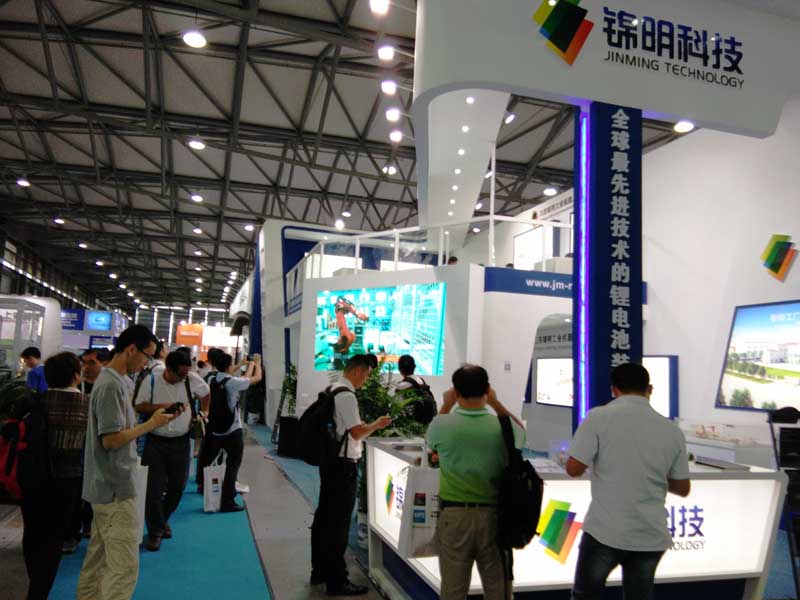

From 24th to 26th August 2016, Shanghai International Automotive Manufacturing Technology & Material Show was held in Shanghai New International Expo Center, and Jinming Technology displayed 18650 lithium battery Pack and module automatic assembly line in the show. During the exhibition, the audience showed great interest in Jinming Technology’s model and promotion video, and they flocked to the booth for consultation.

Jinming Technology can customize world-class assembly automatic solutions, which has highly automatic technological process, and its system has high flexibility, rapid transformation ability. And it also has short period of commissioning and delivering which enables customer can make quick profit. By August, Jinming Technology has build 18650 lithium battery automatic assembly line for Zhongke Taineng, Zotye, Chuhan New Energy, JNMPT, CHJ, etc., which has gained a lot of praise from the customers.

The world advanced 18650 lithium battery assembly line made by Jiangsu Jinming Industrial Robot Automation Co., Ltd has five key design ideas.

1. Highly automatic production line. It can lay out 3 module lines and 1 PACK line, the capacity can be up to 300 PACK/day, the whole line can realize high degree of automation.

2. Highly reliable design. The robots can be used for the realization of core function; the double-station servo sliding table design has been used among each station. It has the features of high precision and easy to transfer. Combined with cache station, they can adopt wide range of product fluctuations, in order to improve production flexibility.

3. Real-time production information. It is equipped with data acquisition and analysis system to meet the demand of MES information acquisition. There’s large television wall equipped in the entrance area which displays the production information of the whole battery line.

4. Manual intervention. When the last/next process has abnormal situation, the products can be put in/take out from transplanting platform by workers. In the meantime, the period can be greatly shortened when debugging.

5. Reduction of non-standard design. It abundantly adopts six-axis standard industrial robots to improve automatic level and stability, like that the speed of battery cells sorting and shell entering is quick and in key position.