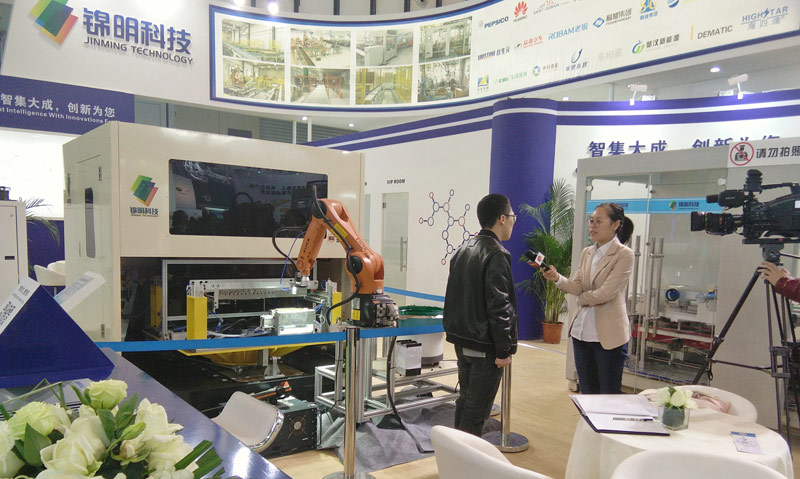

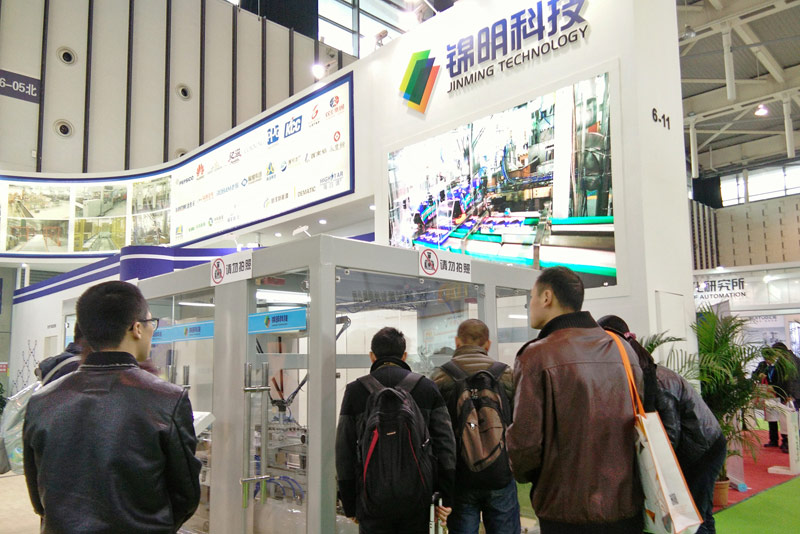

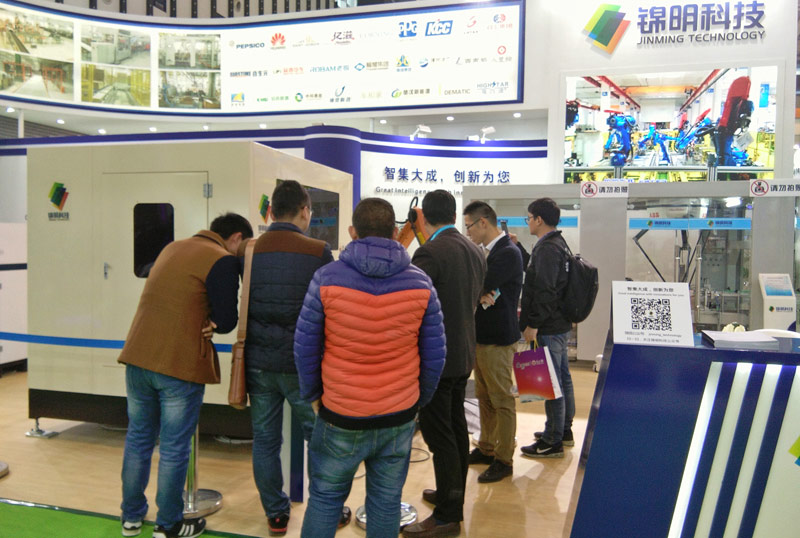

From 6th to 8th December 2016, World Intelligent Manufacturing Summit with the theme of “Work to Integrate and Make it Smarter” was held in Nanjing International Expo Centre. Jinming Technology was invited to attend the exhibition as Jiangsu intelligent manufacturing demonstration enterprise. It displayed a double-station automatic laser welding machine and an all-in-one machine of unpacking, sealing and packing, which has attracted the attention from government leaders, media and a wide audience.

After it was transitioned into the industry of robot and robot system integration application, Jiangsu Jinming has devoted itself to improving its self-developing capability, and the research team has grown strength to strength. At present, it has got 36 national patents, 6 of which are inventions in robot application systems, 29 of which are practical and new patents, and also has got 5 software copyrights. Jinming Technology robot development and application center with first-rate development, design and manufacturing capacity provides advanced and sophisticated intelligent manufacturing solutions for the field of packaging, logistics, assembly, lithium battery equipment and other. Its service industries includes automobile, electronics, food, daily chemical, paper making, etc.

In this World Intelligent Manufacturing Summit, Jinming Technology mainly focused on two themes – “Advance” and ”Intelligence”.

Jinming Technology’s double-station automatic laser welding machine adopts world advanced laser welding technology, which is one of the most important equipment in new energy vehicle square battery module automatic assembly production line. It adopts world advance brand Trumpf’s laser system, which is characterized by high power density, little deformation, narrow heat-affected zone rapid welding speed and other advantages.

Jinming Technology’s all-in-one machine of unpacking, sealing and packing has combined the whole technological process of unpacking, sealing and packing into a machine with the size of 4 m long, 2 m wide and 2 m high. It adopts robot automatic operation, and its stable packing speed is up to 200 cases/min. It does not only save the space, but also it has four wheels, which can realize a flexible layout of the site. This reflects the idea of “robots replace man to work, efficient production and intelligent operation” in intelligent manufacturing.

Robot industry is an important field in the industrial distribution of “Made in China 2025”. A vast number of intelligent manufacturing high-tech enterprises, especially Jinming Technology, are seizing the opportunity to make rapid development, and accelerate the transition of Jiangsu to intellectualization and to become a lead in the new competition.