From 11th to 13th October 2018, the third world intelligent manufacturing summit was held in Nanjing International Expo Center. Huashu Jinming, as a representative of Changzhou intelligent manufacturing enterprises take part in the exhibition in honor. During the exhibition, Zhu Zhihong (Chairman of Changzhou Commissioning of Economy and Information Technology), Liu Xiaoping (Vice Chairman of Changzhou Commissioning of Economy and Information Technology), Cai Yunshen (Director of Society of Automotive Engineers of China) and other leaders came to visit the booth of Huashu Jinming, and looked in detail at Huashu Jinming’s integrated solution of FMCG intelligent factory, integrated solution of new energy automobile power battery module and PACK intelligent factory, and Huashu Jinming big data system.

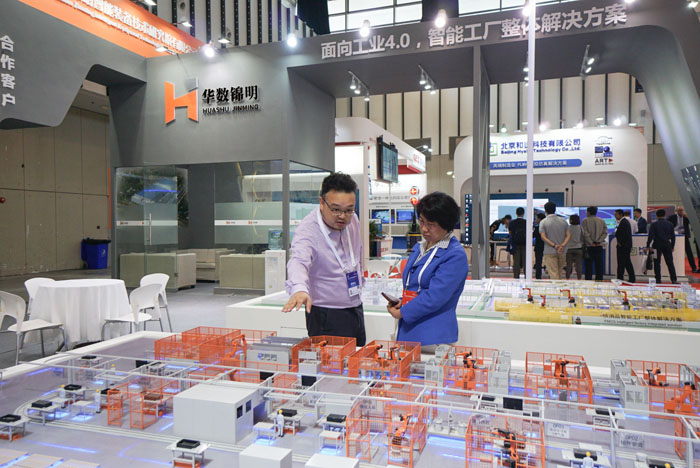

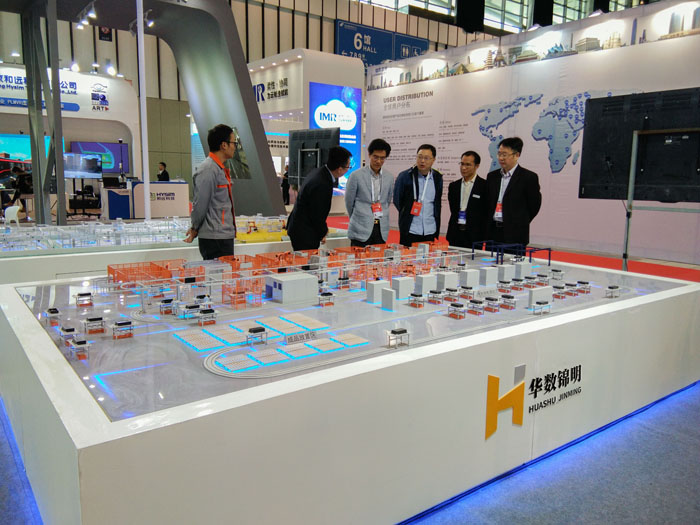

Huashu Jinming’s integrated solution of FMCG intelligent factory supplies a whole factory-level logistics system to customers, including packing, palletizing, transportation, RGV, AGV and automatic stereoscopic warehouse. The whole system takes robot technology as the core, which adopts many advanced industry equipment and technology of flexible transport system, high-speed automatic sorting system, infrared (wireless) communication technology and barcode (vision) detection technology. Huashu Jinming has independently researched factory-level DCS dispatching system software, MES manufacturing management software, and realized dynamic assignment of material by computer dispatching management system. MES manufacturing management system can analyze the system data information, supply visual statements and printing function, and realize the connection with ERP, SAP.

The application of this system has solved the operation problem of many customer production lines, many specifications, high strength hand palletizing and many employees, it has realized concentrated stacking in many specifications which gives priority to carton package. By the technology of “Internet+” and intelligent terminal equipment, it has helped manufacturing enterprise to realize digital management, improve automation level of manufacturing enterprise and create intelligent factory which is conformed to Industry 4.0.

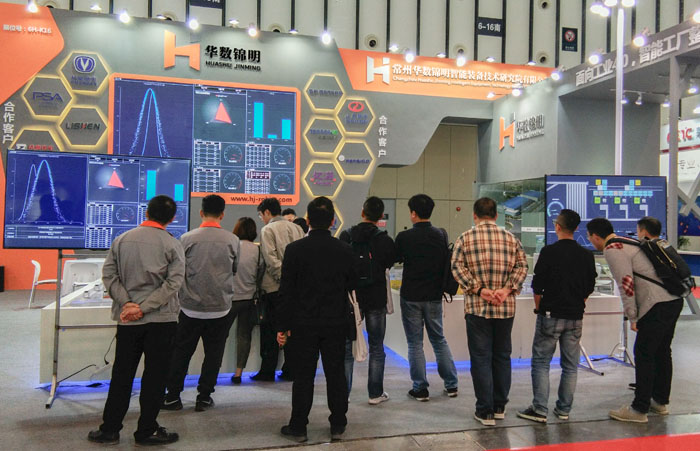

Integrated solution of new energy automobile power battery module and PACK intelligent factory includes cell automatic sorting, shell assembly, screwing, welding, assembly, test, packing and a whole production process. The product range includes 18650 cell electric resistance welding technology, 21700 cell ultrasonic aluminum wire welding technology, prismatic module automatic assembly production line, AGV-PACK line, soft-packed battery automatic assembly line. For now, Huashu Jinming has built dozens of lithium battery module & PACK production lines for various customers, like Changan Automobile, PSA, Lishen Battery, Zotye Automobile, Leapmotor, SF Motors, Sokon, CHJ, Guoxuan High-tech, TESSONNE, Highstar, Chuhan New Energy, and it has gained a certain high popularity in the industry.

For now, intelligent manufacturing is gradually becoming the commanding height of global manufacturing industry revolution and scientific and technological innovation. Changzhou Huashu Jinming are keeping going to explore and practicing in the Industry 4.0 oriented integrated solution of intelligent factory, and making its own contributions to promote Jiangsu into new age of intelligence as soon as possible.